Seabed minerals, be it manganese nodules from the Pacific Ocean, polymetallic crusts from the Arctic spreading ridge, or seafloor massive sulfides from the Indian Ocean, are expected to contain vast amounts of a variety of metals that are essential for the energy transition and for strengthening our mineral value chains.

However, from a mineralogical perspective, these ores may significantly differ from the traditional ores currently extracted on land. Will we be able to extract these metals at processing facilities, and what technologies and methods will be required?

For the deep-sea mining industry to become profitable, processing technologies must be efficient and cost-competitive with land-based mining and recycling methods. In other words, processing will be key to developing a successful industry focused on marine minerals.

At the Deep Sea Minerals 2025 conference in Bergen in April, we are dedicating a session to dive into this topic.

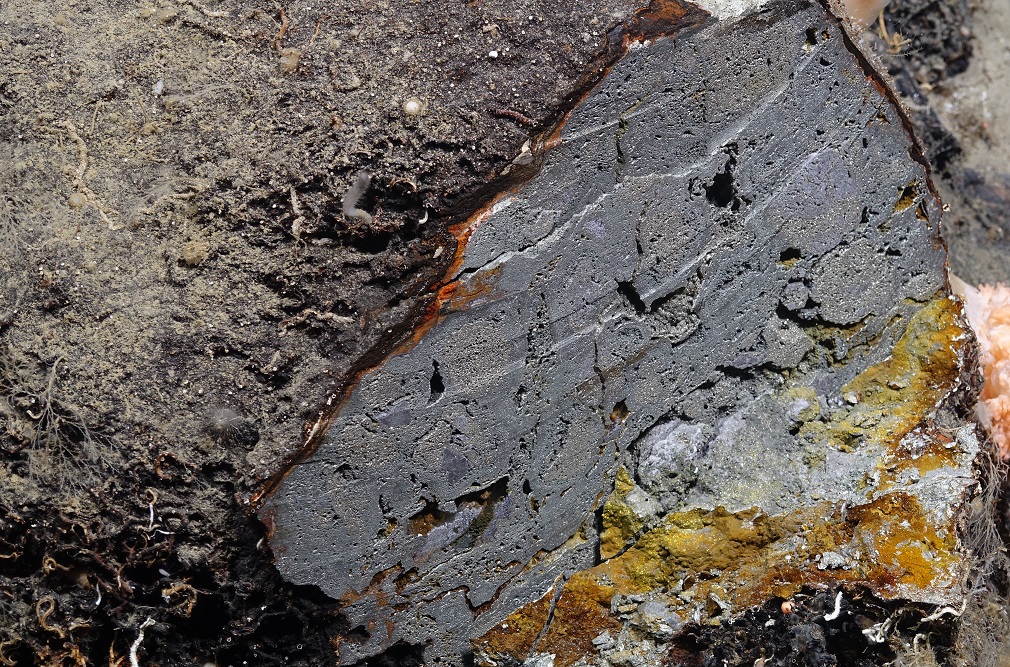

Nina Solvang, project director in Future Materials, will present the results from a study done on sulfide ore collected from the Norwegian Arctic Mid-Ocean Ridge by the EMINENT project in 2023.

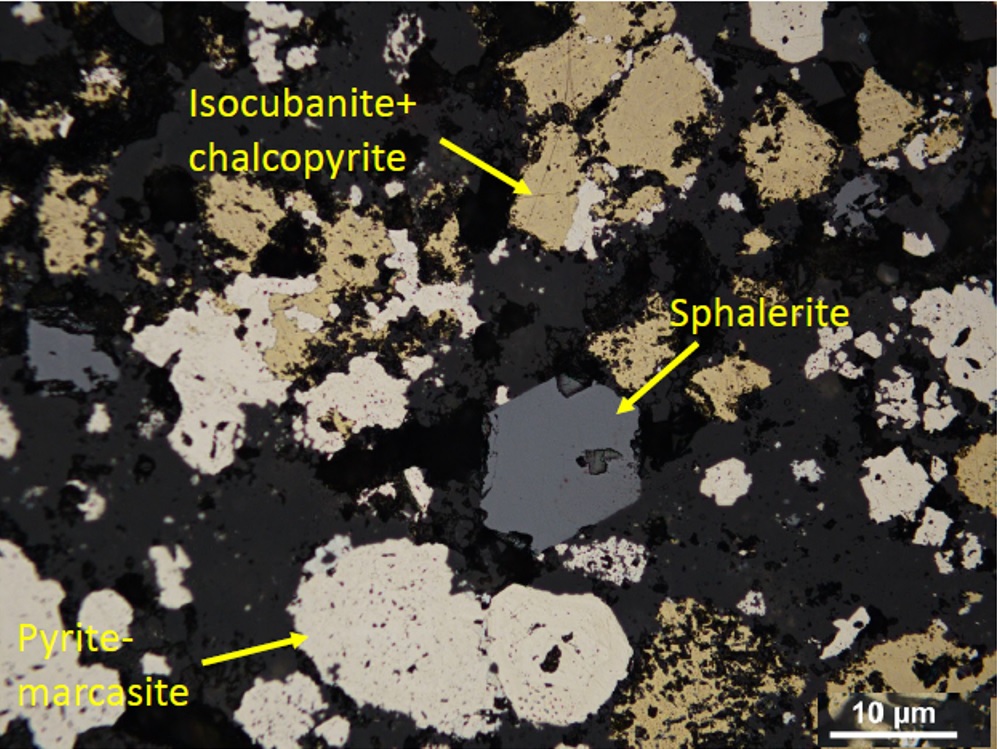

The findings revealed that the ore possesses complex mineralogy, characterized by fine, interlocked mineral grains. The substantial variation in processing responses emphasized the importance of accurately classifying deposits based on their processability.

Solvang will demonstrate that effective recoveries can still be achieved through customized processing techniques, which differ from the methods typically used for copper and zinc-rich ores on land.

Niels Verbaan, director of technical services at SGS Canada, will give us an overview of processing routes under consideration and share results from an internal study on the processing of seabed nodules.

SGS tested high-pressure acid leaching (HPAL) as a processing method, and the results demonstrated excellent recovery rates for nickel, cobalt, and copper. While most manganese, iron, and aluminum remained in the leach residue, these metals can potentially be extracted by further processing using a reductive leach or by pyrometallurgical means.

Verbaan will also provide initial considerations for processing crusts. Crusts contain a variety of metals, including cobalt, vanadium, rare earth elements, and scandium, suggesting several different processing techniques may be required.

As seabed minerals present a new source of materials for the processing industry, comprehensive material characterization and testing are essential to ensure efficient processing.

Deep Sea Minerals 2025 will take place in Bergen from 1-3 April. The program and registration page can be found on the conference website.